-

Graphite Electrodes Low Consumption Strong Electrical Conductivity Wholesale Buyers

Graphite has high thermal conductivity and is very resistant to heat and impact. It also has low electrical resistance, which means it can conduct the large electrical currents needed to melt iron. In recent years, graphite electrodes have been made even more efficient: they can now conduct even higher currents and more power. Using the expertise collected over a century of innovation, Tokai Carbon has developed the world's biggest electrodes. They measure 32 inches (about 80 cm) in diameter and are 3 meters long.

Send Email Details -

Manufacture High Carbon Graphite Electrodes Use for Furnace Industries Hot Sale

Graphite electrodes are used primarily in electric arc furnace steel manufacturing. Graphite electrodes can provide high levels of electrical conductivity and capability of sustaining the extremely high levels of generated heat. Graphite electrodes are also used in the refinement of steel and similar smelting processes.

Send Email Details -

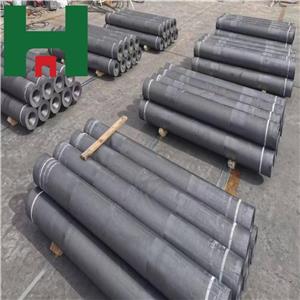

wholesale graphite electrode customized size supply

Graphite electrodes are manufactured using high-quality petroleum coke and needle coke as primary raw materials. These materials undergo blending and baking processes to create the desired electrode properties.

Send Email Details -

Hengqiao Graphite Electrodes Use for Foundries and Ladle Furnaces Electrode Supplier

A graphite electrode is defined as an electrode that is employed to offer high level of electrical conductivity and the capability to sustain extremely high level of dissipated heat. Graphite electrodes are primarily utilized in the manufacturing of electric arc furnace (EAF) steel and refinement of steel, and the equivalent smelting process, like silicon, ferro-alloy, white phosphorus/ yellow phosphorus and etc. By Product , graphite electrode can be classified as: Ultra-high Power (UHP), High Power (HP), Regular Power (RP); By Application, it’s usually defined as Electric Arc Furnace (EAF), Ladle Furnace (LF) &Others.

Send Email Details -

UHP HP SHP high grades graphite electrodes hengqiao supply

Graphite electrodes are manufactured using high-quality petroleum coke and needle coke as primary raw materials. These materials undergo blending and baking processes to create the desired electrode properties.

Send Email Details -

Graphite Electrodes Ultra High Power Electrode Manufacture Supply

The quality of the graphite electrode itself affects the consumption ratio. Nowadays, the smelting and process of electric arc furnaces have higher requirements on the anti-oxidation performance and thermal shock resistance of graphite electrodes. Moreover, the high consumption caused by fluctuations in quality is greatly concerned by users. Therefore, the homogeneity and stability of graphite electrode are the most important factors to determine the consumption.

Send Email Details -

Steel Casting HP Extruded Carbon Graphite Electrode with Nipples

Graphite electrode, with above irreplaceable performance advantages, plays an indispensable role in the high temperature manufacturing field such as iron and steel smelting, electrolytic aluminum, ferroalloy, calcium carbide, industrial silicon and yellow phosphorus smeltingses.

Send Email Details -

high density carbon electrode use for matellurgical furnace

The main reason that graphite electrodes are used in electrolysis is that graphite is an excellent conductor. The structure of graphite is such that it has a large number of electrons floating freely between the different layers of atoms (graphite bonds are formed of only three out of the four electron shells of the carbon atom, leaving the fourth electron to move freely). These electrons act as a powerful conductor, enabling the electrolysis process to progress smoothly. In addition, graphite is economical, stable at high temperatures and hard-wearing. For all these reasons, graphite electrodes are frequently used in electrolysis.

Send Email Details