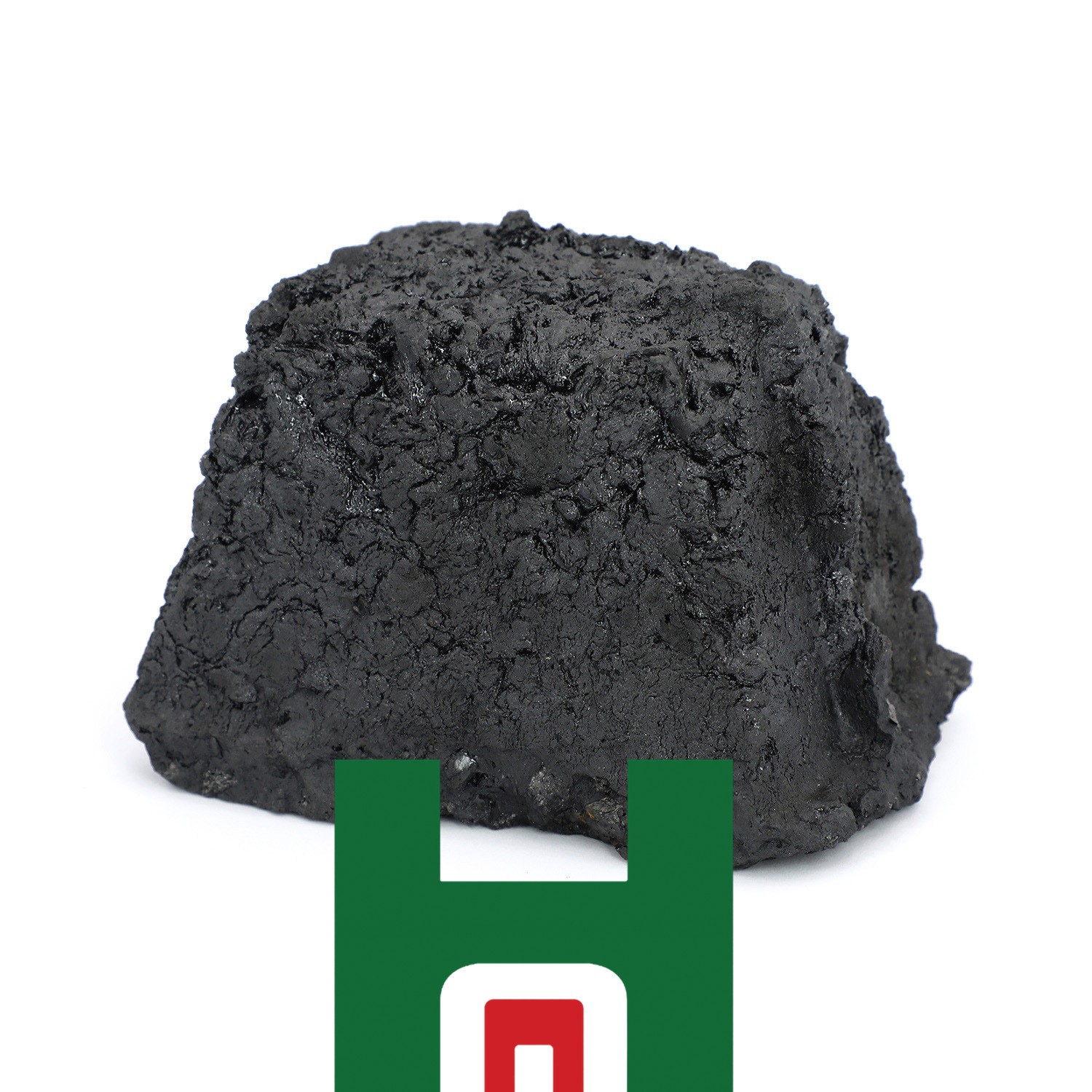

Briquettes Electrode Paste Used in Ferroalloy Plants Saf Furnaces

Brand HQ

Product origin Shandong

Delivery time 7-15 days

Supply capacity 150,000tons

Electrode paste, also known as anode paste, self-baking paste or electrode carbon paste, is often used in ore-smelting electric furnace as conducting material.

Product Description

| Item | Electrode Paste | ||

| Si | <0.28% | Fe | <0.25% |

| P | <0.004% | ||

| Ash Content | 2-10% | Resistivity | 55-90 uΩm |

| V.M | 10.0-15.0% | Density | >1.46g/cm3 |

| Compression Strength | >18Mpa | Extensibility | 6-20 |

| Apparent Density | >1.42g/cm3 | Rupture Strength | >4.0 |

| Real Density | >1.98g/cm3 | Fluidity Coefficient | 1.10-2.10 |

Electrode paste, also known as as anode paste, self-baking paste or electrode carbon paste, is produced from calcined petroleum coke (or calcined pitch coke, electrically calcined anthracite coal), calcined anthracite, coal tar pitch and other additional materials. It comes in a variety of shapes: cylinders, eggs, briquettes and polygonal blocks. It is often used in ion alloy furnace, calcium carbide furnace and other ore-smelting electrical furnaces as conducting material.

In addition, as furnace model various, electrode paste for closed type submerged arch furnaces is called as sealed electrode paste, sealed paste for short; while electrode paste for open type or semi-closed submerged arch furnace is called as standard electrode paste.

Features

Excellent thermal and electrical conductivity.

Low resistance and low porosity.

High temperature resistance, low coefficient of thermal expansion.

High mechanical strength.

Packaging & Shipping

Packing Details: 25kg small bags or 1mt jumbo bag

Port: Tianjin Port, Qingdao Port

Leading Time: Shipped in 15-30 days after payment

Company Profile

Our company has five major production bases, including Lanzhou in Gansu, Linyi in Shandong, Binhai in Tianjin, Ulanqab in Inner Mongolia, and Binzhou in Shandong. The annual output is 200,000 tons of calcined coke, 150,000 tons of graphitized carburizer, and 20,000 tons of silicon carbide.

Exhibitions

Certifications