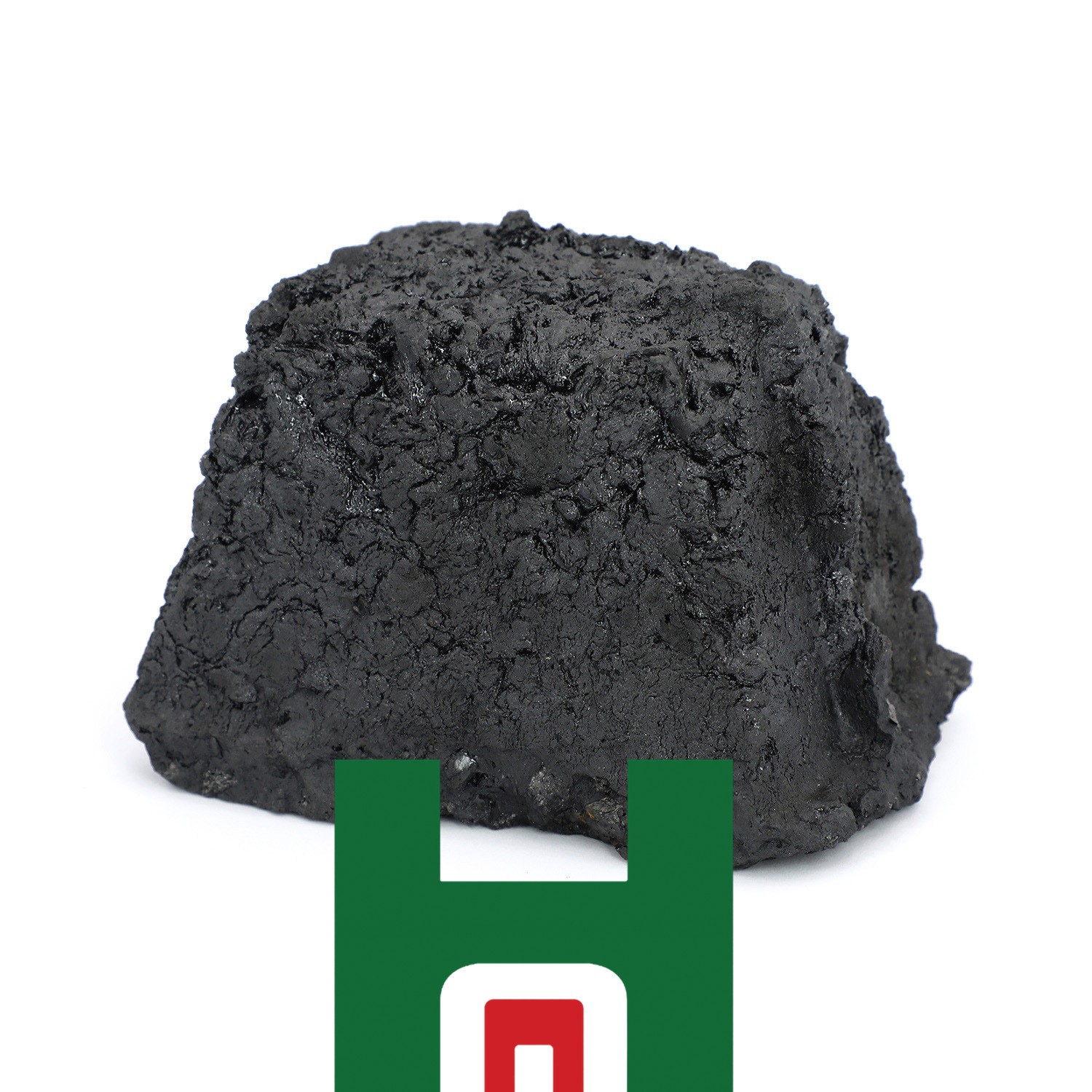

Soderberg Electrode Paste for Ferronickel and Calcium Carbide Smelting

Brand HQ

Product origin Shandong

Delivery time 7-15 days

Supply capacity 150,000tons

Electrode paste is suitable for large scale closed /open typed ferroalloy furnace and calcium carbide furnace , jel1ow phosphor furnace and Wickel ir on furnace. With the features of lov azh content, 1ow electr ical Fesistixitx, strong electric conduction and thermal conductivity, anti oxidation, corrosion resistant. We can produce different products to meet customers' need electrode paste is used in closed electric smelting furnace as continuous self-baking electrode to produce calcium carbide, and ferroalloy. During the furnace operation, electrode paste acts as current conductor.

Product Description

| Item | Electrode Paste | ||

| Si | <0.28% | Fe | <0.25% |

| P | <0.004% | ||

| Ash Content | 2-10% | Resistivity | 55-90 uΩm |

| V.M | 10.0-15.0% | Density | >1.46g/cm3 |

| Compression Strength | >18Mpa | Extensibility | 6-20 |

| Apparent Density | >1.42g/cm3 | Rupture Strength | >4.0 |

| Real Density | >1.98g/cm3 | Fluidity Coefficient | 1.10-2.10 |

Carbon electrode paste is used as self-baking electrodes for submerged arc furnaces, it's a kind of carbon products, consisting of ECA, CPC and graphite powder, with the coal tar pitch as the binder, after the mold shaping. During the application, the paste will be put into the electrode casing from the top side, and the paste will be baked into an electrode finally, as the electrode casing drops down and the temperature comes to the high. The baked electrode will conduct the electricity and transforming the electricity to heat the materials via the electrode peak in furnace.

Packaging & Shipping

Packing Details: 25kg small bags or 1mt jumbo bag

Port: Tianjin Port, Qingdao Port

Leading Time: Shipped in 15-30 days after payment

Company Profile

Our company has five major production bases, including Lanzhou in Gansu, Linyi in Shandong, Binhai in Tianjin, Ulanqab in Inner Mongolia, and Binzhou in Shandong. The annual output is 200,000 tons of calcined coke, 150,000 tons of graphitized carburizer, and 20,000 tons of silicon carbide.

Certifications