Trustable Factory Large Supply Good Quality Silicon Carbide From China

Brand Hengqiao

Product origin Shandong

Delivery time 15-30 days after payment comfirm

Supply capacity 200000 tons/month

Silicon carbide (SiC) is one of the hardest technical ceramics available. For many years it was second only to diamond on the Mohs scale, and to date, sintered silicon carbide remains both a competitive and supplementary material for abrasive synthetic diamonds. Combined with its high thermal conductivity and superb corrosion resistant properties, silicon carbide ceramics are workhorse materials for challenging application areas.

Product Description

ITEM | SIC | Fe2O3 | Al2O3 | Free Carbon | Moisture | Size(mm) |

HQ-SIC-01 | 90% min | 1.5% max | 1.5% max | 3.5% max | 0.5% max | 1-5/1-10 |

| HQ-SIC-02 | 90% min | 1.5% max | 1.5% max | 3.5% max | 0.5% max | 0-10 |

| HQ-SIC-03 | 88% min | 1.5% max | 1.5% max | 3.5% max | 0.5% max | 0-1/1-10 |

| HQ-SIC-04 | 98% min | 0.6% max | 0.6% max | 0.2% max | 0.5% max | 0-1/1-3 |

| HQ-SIC-05 | 70% min | 2% max | 1% max | 10% max | 0.5% max | 1-10 |

Special particle size can be customized according to your requirement. | ||||||

At International Syalons, we offer high-performance silicon carbide ceramics via reaction bonding and sintering. Each manufacturing technique yields a precision zero-porosity ceramic with exceptional resistance to chemical attack and good high-temperature properties. These result from a robust atomic structure with carbon and silicon forming a strong tetrahedral lattice. The advantages of this include:

- Unmatched hardness (2600 Kg/mm2)

- Superior thermal conductivity (150 W/(mK))

- Moderate thermal shock resistance (ΔT = 400°C)

- Good flexural strength at high temperatures (450 MPa at 1000°C)

Sintered silicon carbide is engineered via conventional means, using non-oxide sintering aids and high-temperature forming process in inert atmospheres. Reaction bonding differs in that additional silicon is made to infiltrate the green body to form additional SiC grains that bond with the primary ceramic. The latter is typically used to increase thermal shock resistance.

Packaging & Shipping

Packing Details: 25kg small bags or 1mt jumbo bag

Port: Tianjin Port, Qingdao Port

Leading Time: Shipped in 15-30 days after payment

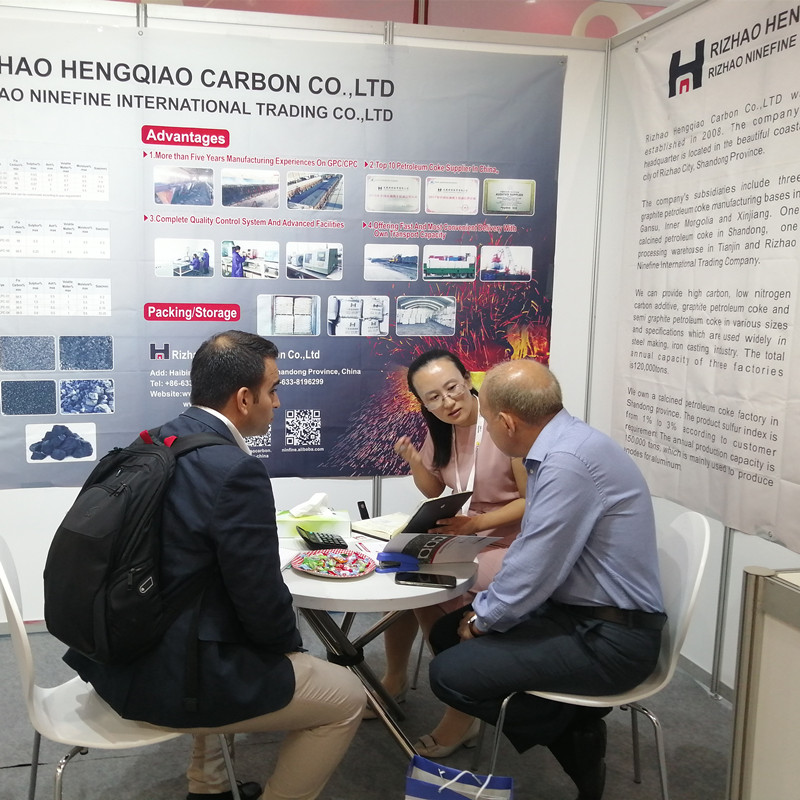

Company Profile

We are the leading manufacturer of carbon additives in China for 10 years, mainly produce graphite petroleum coke, calcined petroleum coke, pet coke and silicon carbide , meanwhile we can trade metallurgical coke and foundry coke as your requirement. The products are widely used in metallurgy, chemical industry, steel-making, casting industry and many fields.

Our company has five major production bases, including Lanzhou in Gansu, Linyi in Shandong, Binhai in Tianjin, Ulanqab in Inner Mongolia, and Binzhou in Shandong. The annual output is 200,000 tons of calcined coke, 150,000 tons of graphitized carburizer, and 20,000 tons of silicon carbide.

Exhibition

Certification

FAQQ1. What is the Warranty for your products?A1. For one year from shipment, If any problem for our goods, we will make prompt response, and take the shipping cost and send replacement.

Q2 . If we need technical support, can you offer us?A2. Yes, we have an experienced team, offering our customers additional benefits with specific advice, by our product management staff, engineers and technicians.

Q3. Do you offer free samples?

A3. Normally we could properly negotiate the sample cost according to detailed requirement.